The primary concern of Activity 8 is the quality control in all steps of the production process of buildings assembled from prefabricated concrete parts. For this, contactless, non-destructive testing methods based on computer vision are to be developed and employed, both in the factory and on the construction site. The specific target qualities and parameters to be measured are identified in cooperation with all the other partners in the research project to both generate the data they need for their analysis and monitor the success of their processes. The quality control is split into two steps, where the prefabricated parts are inspected in the factory for production quality to ensure only suitable parts leave the factory and after assembly on-site to assure the correct placement of the parts and the formation of the joints. The first step is completed using an overhead setup, where a camera is mounted over the production line to capture images. The second phase involves capturing 3D data of the scene and identifying individual parts based on their locations in the BIM models from planning. The results of the analysis are fed back into the BIM models for integrating with all other partners.

Objectives

- Definition of parameters and properties to measure to enable an automated quality control process based on the requirement of the different stakeholders.

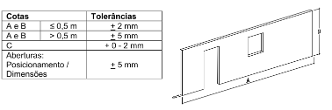

- Design and implementation of a setup for quality control in the concrete factory for the inspection of the dimensions and surface quality of the concrete parts.

- Design and implementation of a setup for quality control on the construction site for the inspection of the placement of assembled parts and the precision of the joints.

- Development of automated methods for the measurement of the part geometry from overhead images before pouring the concrete.

- Development of automated methods for analyzing images of concrete parts with respect to surface quality.

- Development of methods for comparing the as-planned position of concrete parts extracted from BIM models to the as-built position measured after the assembly.